Water vs Oil Quench: Quenching with water is faster and cheaper, but results in a brittle product, while quenching with oil is slower, but produces a product with moderate hardness and less stress. (20 words) Quenching is an essential process in steel heat treating, where a heated metal is rapidly cooled to achieve desired hardness and other properties.

Water and oil are commonly used as quenching mediums in this process, each with its own advantages and disadvantages. This article explores the differences between water and oil quenching, highlighting their effects on the final product’s hardness, brittleness, and cost.

By understanding the characteristics of each quenching medium, manufacturers and metallurgists can make informed decisions to achieve the desired outcome for their specific applications. Let’s delve into the pros and cons of water and oil quenching to determine which method is more suitable for different steel heat-treating processes.

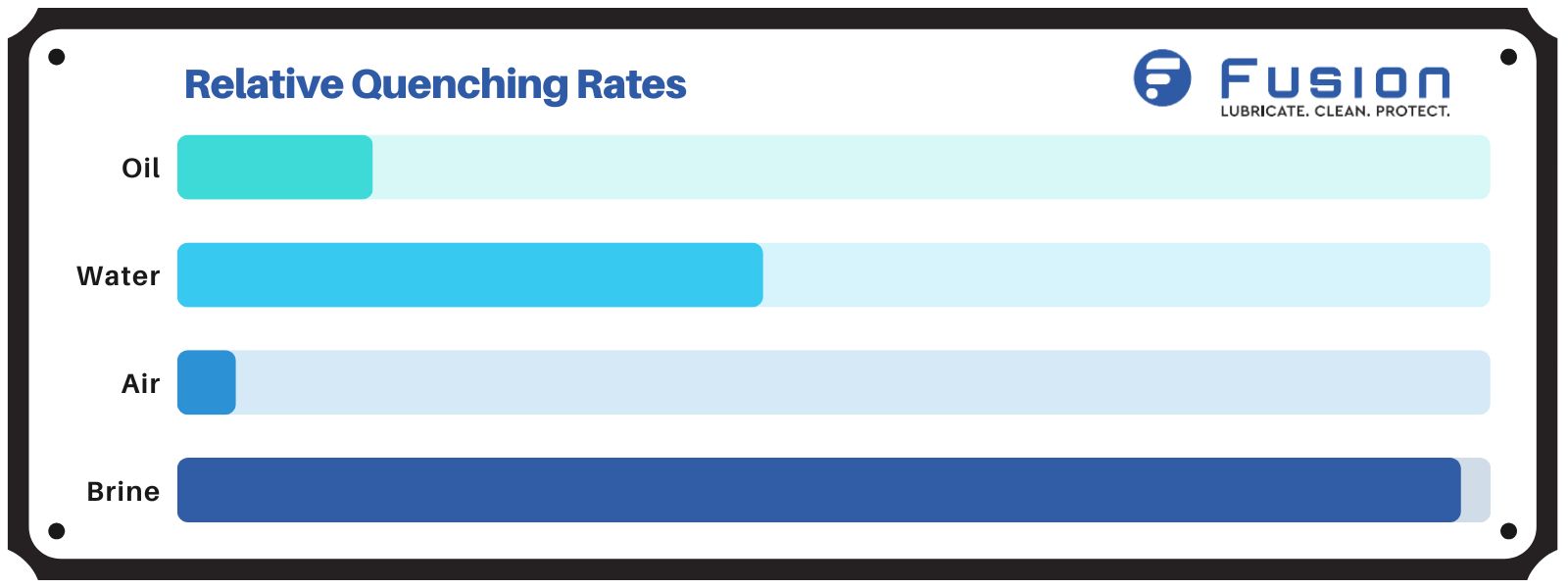

Credit: fusion-chemical.com

Quenching With Water

Quenching with water is a faster and cheaper process compared to oil quenching. However, water quenching often leads to a more brittle end product, while oil quenching results in moderate hardness and less stress, which is generally more desirable. Water’s rapid cooling rate makes it prone to distortion and cracking, while oil offers a more controlled cooling process.

Faster Cooling Rate

Quenching with water offers a significantly faster cooling rate compared to oil quenching. The high specific heat of vaporization and high specific heat capacity of water give it a high quenching power. As a result, water quickly withdraws heat from the heated metal, causing it to cool rapidly.

Brittle End Product

However, one major drawback of quenching with water is that it often leads to a brittle end product. The rapid cooling rate of water persists even at lower temperatures, increasing the likelihood of distortion or cracking in the metal. Therefore, while water quenching may offer a faster and cheaper process, it may not be suitable for applications that require a more ductile and less brittle outcome.

Credit: knifesteelnerds.com

Quenching With Oil

Water vs Oil quench is a debate in the heat treating industry. While water quenching is faster and cheaper, it often results in a brittle product. On the other hand, oil quenching is slower but yields a product with moderate hardness and less stress, which is often preferred.

Slower Cooling Rate

When it comes to quenching with oil, one notable advantage is the slower cooling rate compared to water quenching. This slower cooling rate allows for more controlled and gradual cooling of the heated metal, reducing the risk of thermal shock and cracking. The oil acts as a buffer, absorbing and dissipating heat at a slower pace, which is particularly beneficial for certain types of steel and alloys.Moderate Hardness

Quenching with oil typically results in a product with moderate hardness. The slower cooling rate allows for a more gradual transformation of the metal structure, leading to a balanced hardness level. This moderate hardness is often desirable, as it provides the ideal combination of strength and toughness. Oil quenching is commonly favored for applications where a harder but less brittle end product is required.Less Stress

Another advantage of quenching with oil is the reduced stress on the metal. The slower cooling rate and moderate hardness achieved through oil quenching minimize the internal stresses that can arise from rapid cooling. This not only helps prevent distortion and cracking but also ensures better dimensional stability and overall structural integrity of the product. The decreased stress levels make oil quenching a preferred method for certain types of components and materials. In conclusion, quenching with oil offers distinct advantages such as a slower cooling rate, moderate hardness, and less stress on the metal. These factors contribute to achieving a desired balance of hardness and toughness while minimizing the risk of cracking and distortion. Depending on the specific requirements of the application, oil quenching can be a superior choice over water quenching.Advantages And Disadvantages

Water quenching is a faster and cheaper process than oil quenching, but it often results in a brittle end product. On the other hand, quenching with oil is slower but produces a product with moderate hardness and less stress.

Water As A Quenchant

Using water as a quenchant has its advantages and disadvantages. One advantage is that it is a much faster and cheaper process compared to oil quenching. Water has a high quenching power due to its high specific heat of vaporization and high specific heat capacity. This means that it can rapidly cool the steel, resulting in a hard and strong end product. However, the rapid cooling rate of water persists throughout the lower temperature range, increasing the likelihood of distortion or cracking in the steel. Additionally, water quenching tends to produce a more brittle end product.Swords Quenched In Oil Or Water

When it comes to quenching swords, there is a choice between using oil or water. Water quenching is a faster cooling method compared to oil quenching, which means that it hardens the blade more quickly. As a result, water quenching can produce a harder blade, making it suitable for swords and axes that require a high level of hardness. However, the trade-off is that the blade becomes more brittle, which can increase the risk of breakage.Effect On Steel Hardness

The choice between water and oil quenching can have a significant impact on the hardness of the steel. Quenching with water tends to result in a brittle end product, as the rapid cooling rate can cause the steel to become overly hard and prone to cracking. On the other hand, quenching with oil has a slower cooling rate, which allows the steel to harden to a moderate level while minimizing the risk of stress and brittleness. This makes oil quenching the more desirable option in certain applications where a balance of hardness and strength is required. In conclusion, the choice between water and oil quenching depends on the desired outcome for the steel. Water quenching offers a faster and cheaper process, but it can result in a more brittle end product. Oil quenching, although slower, provides a moderate hardness and less stress, making it a preferred choice in applications that require a balance of hardness and strength.

Credit: knifesteelnerds.com

Frequently Asked Questions On Water Vs Oil Quench

Is It Better To Quench In Oil Or Water?

Quenching with oil or water depends on the desired outcome. Water quenching is faster and cheaper but can result in a brittle product. Oil quenching is slower but produces a product with moderate hardness and less stress, which is typically preferred.

Why Is Water Not Used For Quenching?

Water is not used for quenching because it cools too quickly and can result in a brittle end product. Quenching with oil is slower, but it produces a product with moderate hardness and less stress.

Are Swords Quenched In Oil Or Water?

Swords are typically quenched in oil. It results in a product with moderate hardness and less stress. Water quenching is faster but can make the blade brittle.

Does Water Quenching Make Steel Harder?

Water quenching can make steel harder, but it may also result in a more brittle end product. Oil quenching is slower, but produces a product with moderate hardness and less stress.

Conclusion

Quenching with water or oil has its advantages and disadvantages. Water quenching is faster and more cost-effective, but it often results in a brittle end product. On the other hand, oil quenching is slower but produces a product with moderate hardness and less stress.

The choice between water and oil quenching depends on the desired outcome and the specific requirements of the steel being treated. It is important to consider factors such as hardness, distortion, and cracking when deciding which method to use. Overall, understanding the differences between water and oil quenching is crucial for achieving the desired hardness and quality in steel products.

Minhajul Islam is a passionate technology writer and the founder of DifferencePlanet. He is dedicated to exploring the latest advancements in the tech industry and sharing his insights with the world. With a background in computer science and a keen interest in smart homes, Minhajul has written numerous articles on a wide range of tech topics. He believes that technology has the power to transform the way we live, work, and interact with the world around us, and is always on the lookout for the next big thing.